Transforming Post-Plasma Cutting with Advanced Surface Solutions

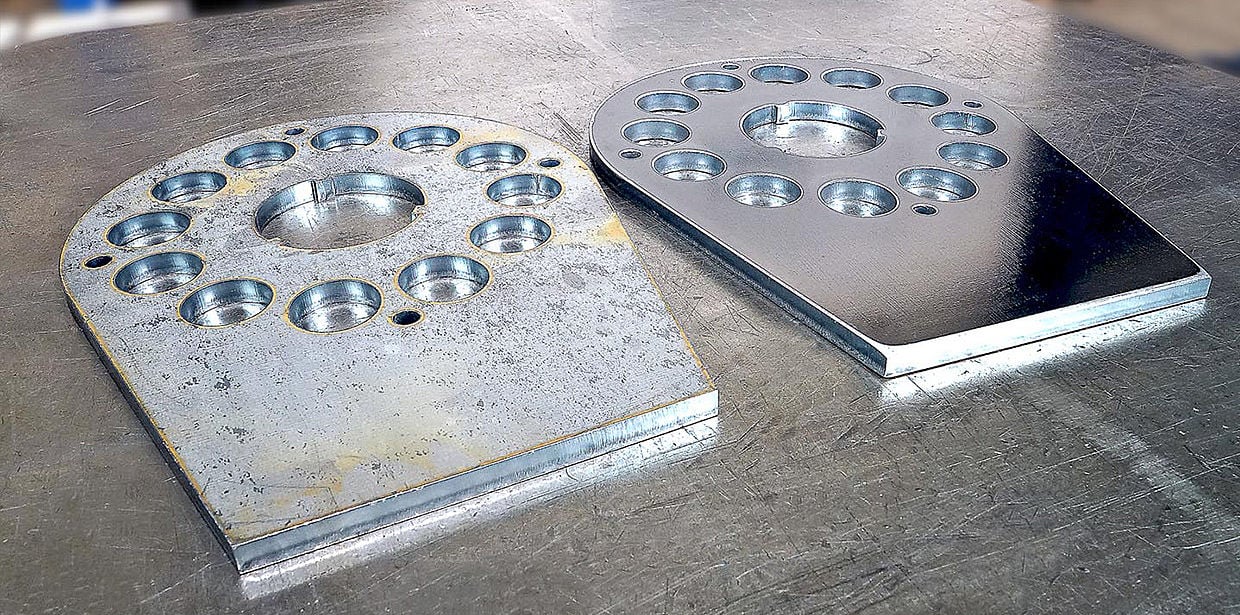

Plasma cutting is a widely used technique for shaping metals, known for its precision and speed. However, the process often leaves behind hardened slag and burrs that can compromise the finish and functionality of cut components. The Plasma Cutter Slag Deburring Machine is designed to eliminate these imperfections with unmatched accuracy, ensuring every workpiece is smooth, safe, and ready for the next stage of fabrication. Valgro India offers a state-of-the-art solution that redefines how manufacturers handle post-cut surface refinement.

Challenges of Plasma-Cut Slag and the Need for Precision Deburring

Slag and burrs left after plasma cutting can hinder downstream processes such as welding, coating, or assembly. Manual removal is labor-intensive and inconsistent, especially when dealing with high volumes or thick materials. The Plasma Cutter Slag Deburring Machine addresses these challenges with automation and precision. It effectively removes slag, levels uneven surfaces, and rounds edges without damaging the integrity of the metal. This results in a cleaner, safer, and more professional finish, critical for high-performance industries.

Precision Engineered for Demanding Metal Applications

Designed to tackle the tough slag produced by plasma cutting, the Plasma Cutter Slag Deburring Machine uses a combination of abrasive technology and adjustable pressure settings. This allows it to adapt to various material types including steel, stainless steel, and aluminum. Whether it’s heavy plate or thin sheet, the machine delivers a refined finish while preserving the geometry and strength of the part. Valgro India’s innovative design makes it suitable for sectors such as automotive, structural steel, fabrication, and machinery manufacturing.

Boosting Throughput While Ensuring Consistent Surface Quality

High-volume production demands equipment that can keep pace without compromising quality. The Plasma Cutter Slag Deburring Machine excels in speed and consistency, allowing operators to process multiple parts in less time compared to manual grinding or less efficient alternatives. Its automated system ensures uniform surface refinement, so each component meets exact specifications. This consistency is vital for industries where every detail matters, from structural integrity to paint adhesion.

Durable Construction Built for Industrial Environments

The Plasma Cutter Slag Deburring Machine by Valgro India is engineered to handle tough shop-floor conditions. Its robust construction ensures long-lasting performance even under continuous use. Built with industrial-grade components and reliable drive systems, the machine requires minimal maintenance while delivering high-efficiency deburring. Operator-friendly controls and intuitive interfaces make it easy to use, reducing training time and increasing productivity across shifts.

Clean and Eco-Conscious Finishing Process

Manufacturers are increasingly focused on sustainability and cleaner operations. The Plasma Cutter Slag Deburring Machine supports eco-friendly practices by reducing airborne dust and eliminating the need for chemical-based surface treatments. Integrated dust collection systems help maintain a clean working environment, while energy-efficient motors minimize power consumption. This combination of performance and sustainability makes it a smart investment for environmentally responsible operations.

Customized Performance for Industry-Specific Needs

Every manufacturing operation has unique requirements. Valgro India offers tailored solutions so each Plasma Cutter Slag Deburring Machine can be configured to suit specific applications. Whether it’s adjusting brush types, conveyor speed, or working width, the flexibility of the machine allows it to align with existing production lines. This adaptability helps manufacturers streamline their operations and achieve consistent results across diverse projects.

Reliable Support and Long-Term Value

Investing in a Plasma Cutter Slag Deburring Machine from Valgro India means more than acquiring advanced equipment. Clients receive full technical support, from machine setup to operator training and routine maintenance guidance. This commitment ensures uninterrupted performance and maximum return on investment. With years of experience and industry knowledge, Valgro India stands behind its machines with confidence and customer-focused service.

Innovation Driving the Future of Post-Cut Processing

As manufacturing demands evolve, so must the technology that supports it. The Plasma Cutter Slag Deburring Machine continues to evolve with smarter features, improved material handling, and digital integration. Valgro India is actively developing next-generation enhancements to meet the future of automated surface refinement. These innovations will help manufacturers maintain their competitive edge in a market that demands both speed and perfection.

Conclusion – Precision Deburring That Powers Progress

The Plasma Cutter Slag Deburring Machine is not just a solution; it’s a transformation in how industries approach post-cut surface treatment. With its powerful slag removal capabilities, consistent performance, and ability to deliver ready-to-process parts, it plays a critical role in modern fabrication lines. Valgro India continues to lead with dependable, high-quality machines that help manufacturers raise their standards, improve efficiency, and achieve excellence in every cut.