Proper storage and handling of Hydraulic Oil on construction sites are essential to maintain its quality and effectiveness. Even the highest-grade hydraulic oil can degrade rapidly if exposed to contaminants, moisture, or improper storage conditions. Following best practices in storage and handling ensures that the oil retains its protective properties, reduces the risk of equipment damage, and supports efficient machine operation.

Storage Conditions

Hydraulic oil should be stored in a clean, dry, and temperature-controlled environment. Exposure to extreme temperatures—whether excessive heat or freezing cold—can adversely affect the oil’s viscosity and additive performance. Ideally, storage areas should maintain a consistent temperature, shielded from direct sunlight and heat sources. This stability preserves the oil’s chemical integrity over time.

Containers used for storing hydraulic oil must be airtight and sealed tightly when not in use. Open or poorly sealed containers can allow moisture and airborne contaminants to enter, leading to oxidation, emulsification, and premature oil degradation. Using original manufacturer packaging or dedicated drums with secure lids is recommended.

Preventing Contamination

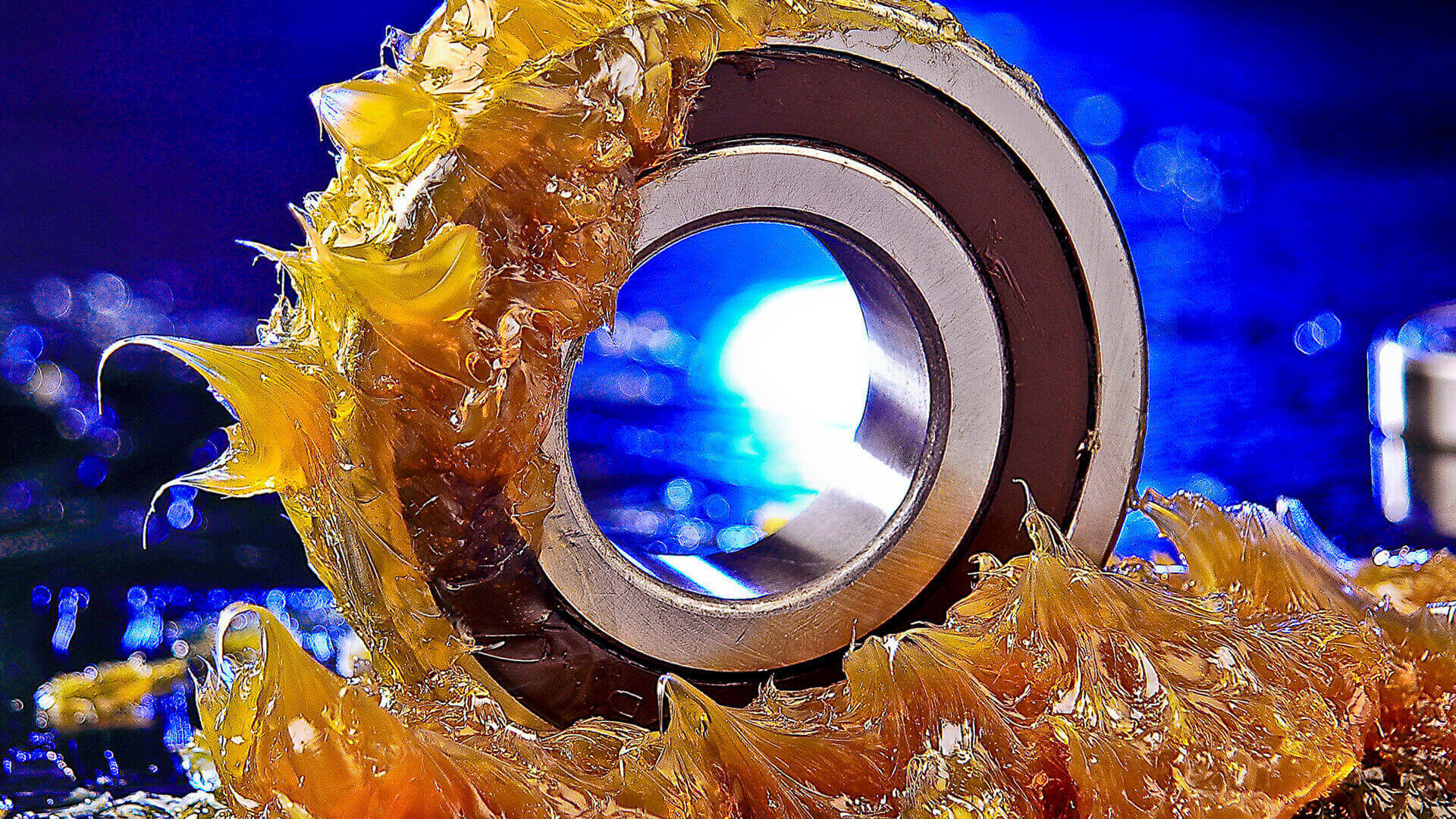

Contamination is the leading cause of hydraulic oil failure on construction sites. Dirt, dust, water, and other foreign particles can enter the oil during storage or transfer and cause abrasion, corrosion, and blockage in hydraulic systems. To prevent contamination, always use clean, dedicated funnels and transfer equipment when dispensing hydraulic oil.

Sites should implement strict cleanliness protocols around storage tanks, transfer pumps, and dispensing areas. Covering oil containers when not in use and cleaning all tools before contact with hydraulic oil helps minimize the risk of dirt ingress.

Water contamination is particularly harmful. Even small amounts of water in hydraulic oil can reduce lubrication quality, promote rust, and cause foaming or erratic system behavior. Regularly inspecting seals and storage containers for leaks and using water-separating filters can help prevent moisture buildup.

Handling Procedures

When handling hydraulic oil, it is crucial to follow proper safety and operational guidelines. Personnel should wear appropriate protective equipment such as gloves and goggles to avoid direct contact, as hydraulic oils can irritate skin or eyes.

During oil transfer or refilling of machinery reservoirs, slow and controlled pouring reduces the chance of spills and splashing, which not only wastes oil but also increases contamination risks. Using dedicated pumps or closed transfer systems can further improve safety and cleanliness.

Maintaining a log of oil batches and storage durations is also a good practice. This allows for tracking oil age, ensuring older stock is used first to avoid extended storage times that might compromise oil quality.

Regular Inspection and Testing

Even with optimal storage, hydraulic oil should be inspected regularly for signs of contamination or degradation. Visual checks for discoloration, cloudiness, or sediment can provide early warning. Additionally, periodic oil analysis for water content, particle contamination, and viscosity can confirm the oil’s condition before use.

Implementing a routine testing schedule as part of your preventive maintenance plan helps avoid equipment failure caused by poor-quality oil. Any oil found to be contaminated or outside recommended specifications should be properly disposed of and replaced promptly.