Understanding the Role of Small Batch PCB Solutions in Modern Manufacturing

Small Batch PCB Solutions are becoming increasingly important for startups, product developers, and companies looking to test their designs before large-scale manufacturing. This approach allows businesses to produce a limited number of printed circuit boards with the same quality and precision as mass production runs. By opting for Small Batch PCB Solutions, companies can minimize risks, control costs, and make quick adjustments without the burden of producing excessive quantities. This flexibility is crucial for industries where innovation moves rapidly, and prototypes need to evolve quickly.

Why Small Batch PCB Solutions are Ideal for Prototyping

Prototyping is a critical phase in the development of electronic products, and Small Batch PCB Solutions are the perfect fit for this stage. They enable designers and engineers to test their concepts with real, functional boards before committing to large-scale production. By producing only what is needed for evaluation, businesses can identify design flaws early, improve layouts, and ensure performance standards are met. This approach not only saves money but also reduces the time required to bring a product from concept to market.

Quality Standards in Small Batch PCB Solutions

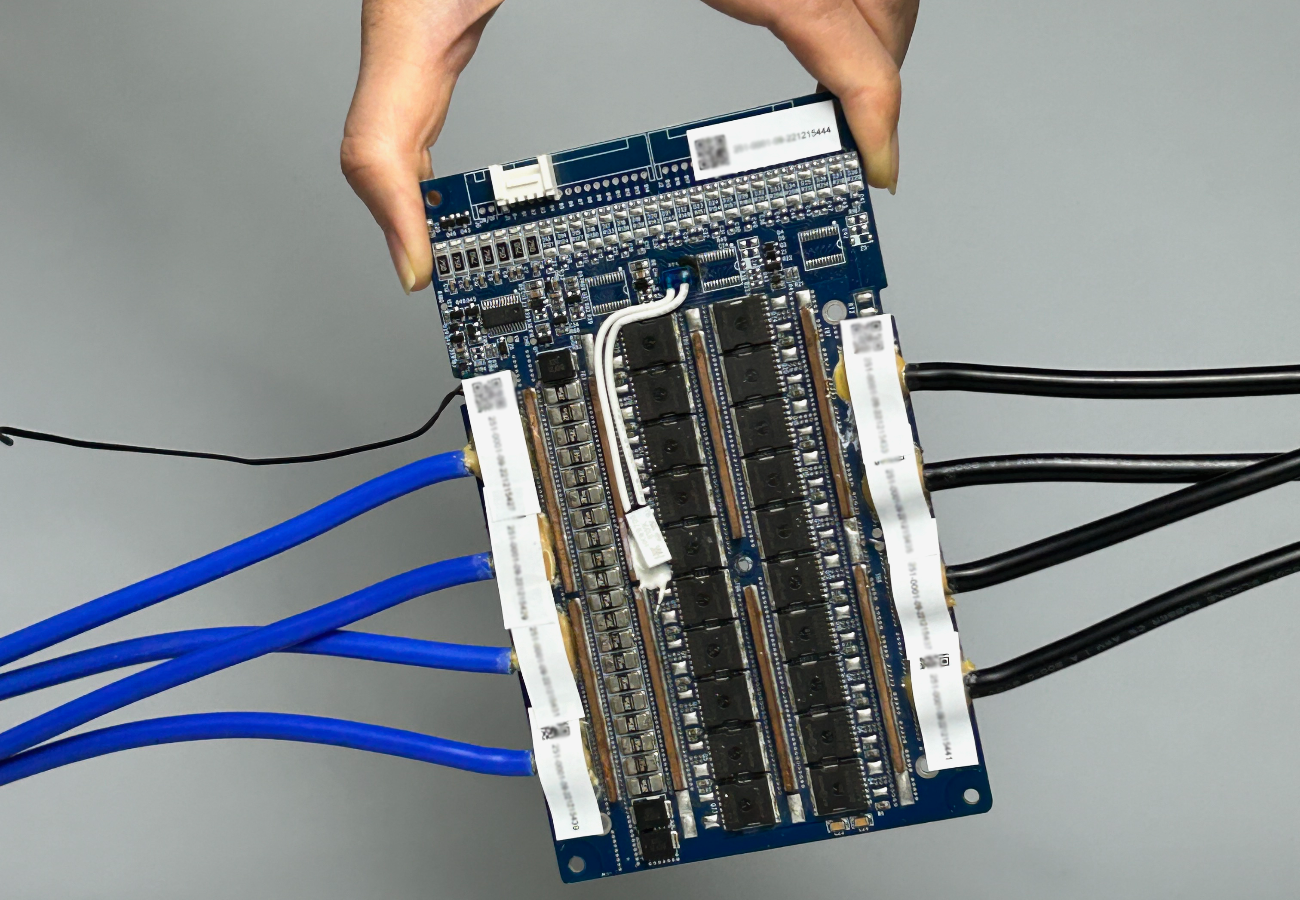

Despite the smaller production volume, Small Batch PCB Solutions maintain strict quality control measures. Advanced manufacturing techniques, precision machinery, and thorough inspection processes are used to ensure every board meets the required specifications. Surface-mount technology, through-hole assembly, and mixed-technology designs are all achievable with the same level of attention and care as high-volume orders. This guarantees that businesses receive boards with reliable performance, durability, and consistency, regardless of the production scale.

Cost Efficiency Through Small Batch PCB Solutions

One of the most appealing benefits of Small Batch PCB Solutions is cost efficiency. Businesses avoid the large upfront investment typically associated with mass production while still benefiting from professional-grade manufacturing services. This approach also helps reduce waste since only the necessary quantity of boards is produced. For startups or smaller companies, this can mean allocating resources to other areas such as product testing, marketing, or design improvements without compromising on quality.

Technological Advantages in Small Batch PCB Solutions

Today’s Small Batch PCB Solutions are supported by advanced equipment and software that enable precise, fast, and reliable production. Automated pick-and-place machines, high-resolution imaging systems, and cutting-edge soldering techniques ensure that even small production runs meet the highest industry standards. Additionally, manufacturers offering these solutions often provide rapid turnaround services, allowing businesses to receive their boards in just a few days. This speed is essential for companies aiming to stay ahead in competitive markets.

Flexibility and Customization in Small Batch PCB Solutions

Every product is unique, and Small Batch PCB Solutions offer the flexibility to customize designs to meet specific needs. From material selection and layer count to special finishes and component types, clients have full control over their board specifications. This level of customization ensures that the final product aligns perfectly with the intended application, whether it is for consumer electronics, medical devices, automotive systems, or industrial controls. Such tailored solutions empower businesses to create innovative products without the limitations often associated with mass production.

Choosing the Right Partner for Small Batch PCB Solutions

Selecting the right manufacturing partner for Small Batch PCB Solutions is essential for success. Experienced providers not only deliver top-quality boards but also offer valuable guidance during the design and production stages. They work closely with clients to identify potential improvements, ensure component compatibility, and streamline the overall process. A reliable partner can make the difference between a smooth, efficient production run and one plagued by delays or quality issues.

Conclusion – The Value of Small Batch PCB Solutions

Small Batch PCB Solutions provide a perfect balance between quality, cost efficiency, and flexibility. They allow businesses to test, refine, and launch products with confidence while keeping production volumes manageable. By offering the same level of precision and durability as high-volume manufacturing, these solutions empower innovators to bring their ideas to life without unnecessary risk or expense. In an industry where speed, accuracy, and adaptability are key, Small Batch PCB Solutions stand out as a smart and strategic choice for modern electronics production.